W9000 & W9500

Lightweight corrosion resistant flap valves for the prevention of reverse flows.

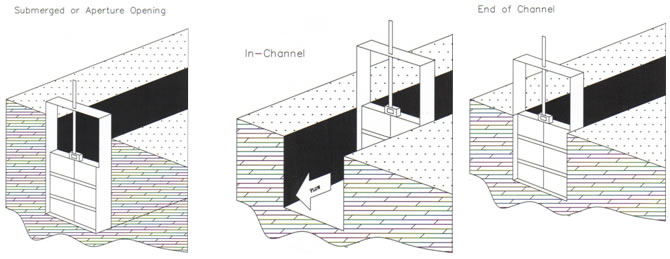

Flap valves are designed and manufactured for use in modern industrial and domestic effluent environments and for protected river and sea outfalls with gravity flows. Utilisation of the latest materials combined with the strength of steel or stainless provides a range of flap valves having strength and rigidity but which are very sensitive to small differential heads.

Rectangular flap valves are available in sizes 450mm sq up to 3200mm sq as standard. Larger and smaller sizes plus rectangular sizes are available to suit individual requirements. Circular flap valves are available in sizes 80mm bore to 600m bore only.

Pressure Drop across the Flap Valve

The approximate pressure drop across a flap valve is a function of the Velocity head of the fluid passing through it and its size.

- Corrosion resistance

- Lightweight

- Low cracking heads

- Low maintenance

- Lower installation costs using expanded anchor bolts

- Choice of frame material

- Mechanically fixed renewable seals

- Custom built to customers requirements

450sq mm up to 2000mm square or any rectangular size within these limitations. Larger sizes can be accommodated depending on pressure and duty.

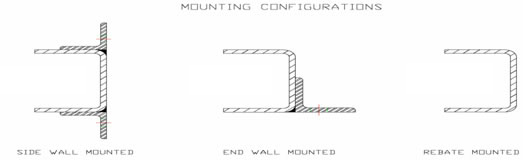

Standard fixing arrangements is wall fixing on to a flat vertical wall. Note: It is recommended that at least 300mm fall away is provided at the invert to prevent fouling of the bottom of the floor.

Top bottom and side pressed members produce a sloping surface which will guarantee closure in balanced or dry conditions.

Frames and doors are manufactured from mild steel to BS4360 GR43A or stainless steel to BS970 or BS1449 grades 304 or 316.

Mild steel frames as standard are blast cleaned after fabrication to SA2 2/2 minimum quality zinc sprayed to 100 microns nominal thickness (75 microns minimums) etch primed and finished with two coats of coal tar epoxy or high build bituminous paint (potable water), 75 microns per coat.

For sea water applications paint thickness is increased to 225 microns DFT. Stainless steel frames are natural finish.

Is an EPDM (Ethylene Propylene) wiper type seal having an angled lip seal. EPDM (Ethylene Propylene) is chosen for its greater resistance over Neoprene to ultra violet degradation.

The seal is fixed with a corresponding Resistant retaining strip and stainless steel fasteners.