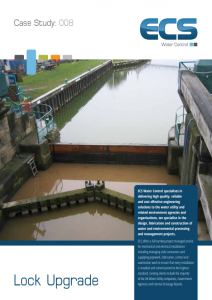

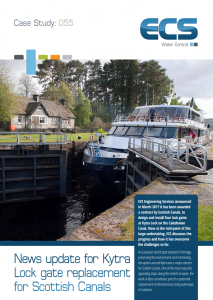

Lock gates make transit along UK waterways possible and maintaining these essential structures is vital to keep them functioning properly.

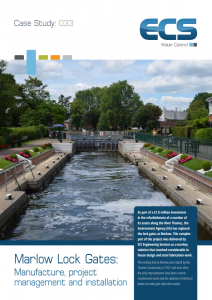

Working closely with lock owners, ECS has considerable experience in working on large water control structures that ensures projects are delivered safely and on time.ECS has the skills and facilities to deliver complete turnkey projects for the refurbishment of lock complexes.

With in-house steel fabrication and an exclusive UK agreement with Fibercore Europe which creates fibre reinforced plastic (FRP) lock gates, ECS is perfectly positioned to deliver replacement lock gates across the country.