Large Fort Augustus lock gates fabricated by ECS

Large Fort AugLeading solutions provider to the water industry, ECS Engineering Services, has leveraged its fabrication capabilities to manufacture six sets of lock gates for the Fort Augustus flight on the Caledonian Canal. The new gates are among the largest in the country, with canal operator Scottish Canals relying on ECS to deliver the project as its single source framework contractor for lock gates.

The Caledonian Canal is one of the foremost tourist attractions in Scotland, incorporating the iconic waters of Loch Ness and stunning natural scenery. Constructed in the 19th century to offer shipping an easier trade route than the North Sea, the canal also has a rich history rooted in the industrial revolution. Fort Augustus is located to the west of Loch Ness, with its gates controlling water levels upstream. The challenge for the fabrication team at ECS was to produce gates to the required size and quality, while preserving the historical heritage of the original design.

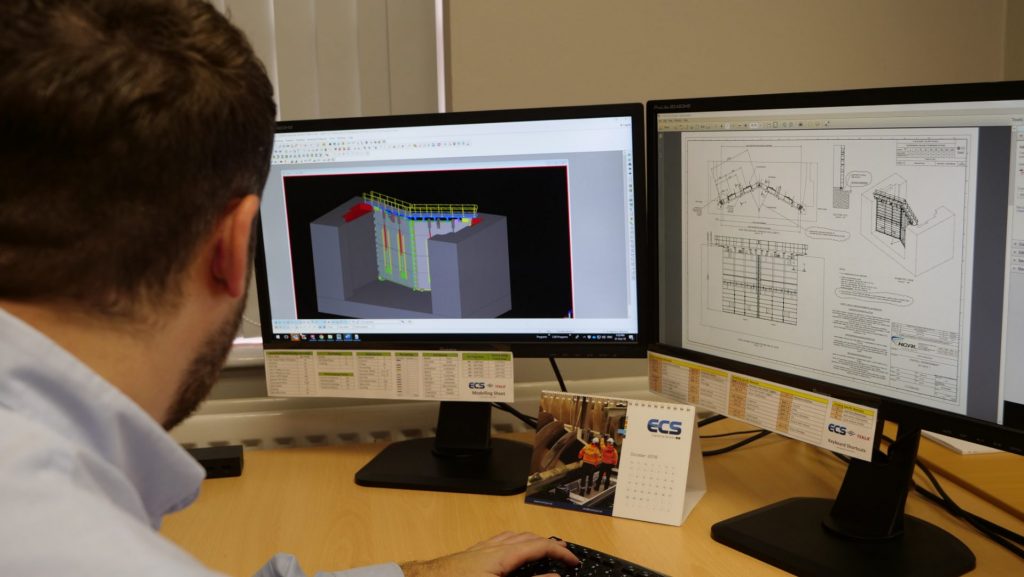

Matt Enright, Production Manager at ECS, was heavily involved in the project: “As a framework contractor for Scottish Canals, we have prior experience in delivering fabrication projects of this scale. Our fabrications team recently delivered two sets of gates for Kytra Lock on the same stretch of water, so it was a case of scaling up our approach. At our facility in Sutton-in-Ashfield, we operate design offices in close proximity to the fabrications department, which ensures a seamless transition of information between both, reducing project lead times.”

Working in conjunction with water control design partner KGAL, ECS Engineering Services drew up plans for each of the six lock gate sets. Particular attention was paid to preserving the aesthetic of the original gates, blending modern fabrication standards with a historical outward appearance.

Matt continues: “A key concern before we could begin welding was how to safely turn and move these large gates during the fabrication process. Prior to work beginning, as a team, we reviewed the process for moving the gates inside the facility and were able to effectively minimise risk during the fabrication process. Once this was finalised, work could begin.

“We had to fabricate each steel lock gate to CE Marking BS EN Execution Class (EXC) 2, which ensured the steelwork was suitable for the challenging duty requirements of the lock gate application. ECS is accredited to EXC4 – the highest available – so this was well within our capability.”

The end result was six sets of lock gates that matched the project specifications and are highly durable. Fabrication work was conducted entirely in-house, allowing each completed gate to be transported to Fort Augustus completed for prompt installation. This served to minimise the disturbance caused by the project, especially important in a scenic tourist hotspot.

Matt concludes: “Our experience in similar fabrication projects means we have a highly competent workforce and suitable equipment that can take on projects of this scale. This capability ensured we could deliver this large order effectively, and exactly to the requirements of Scottish Canals.”

Working in conjunction with water control design partner KGAL, ECS Engineering Services drew up plans for each of the six lock gate sets.

ECS Engineering Services, has leveraged its fabrication capabilities to manufacture six sets of lock gates for the Fort Augustus flight on the Caledonian Canal.

Fabrication work was conducted entirely in-house, allowing each completed gate to be transported to Fort Augustus completed for prompt installation.